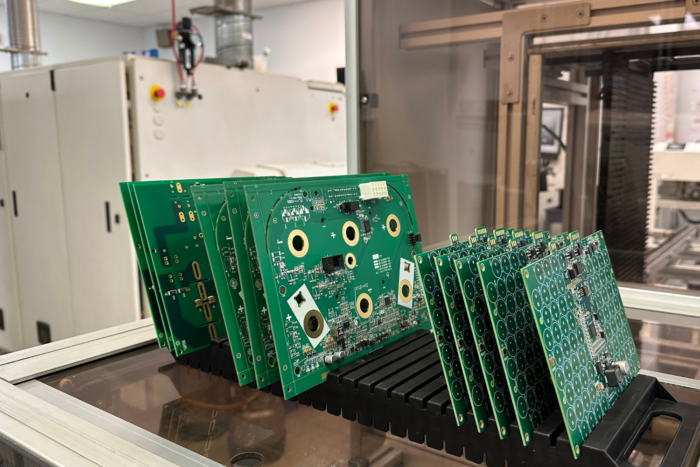

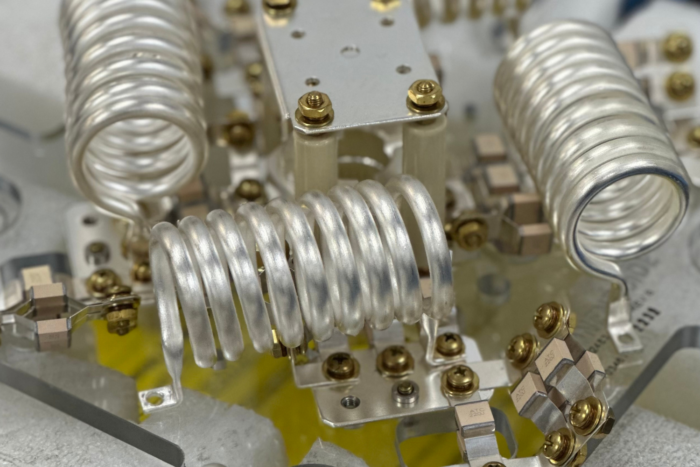

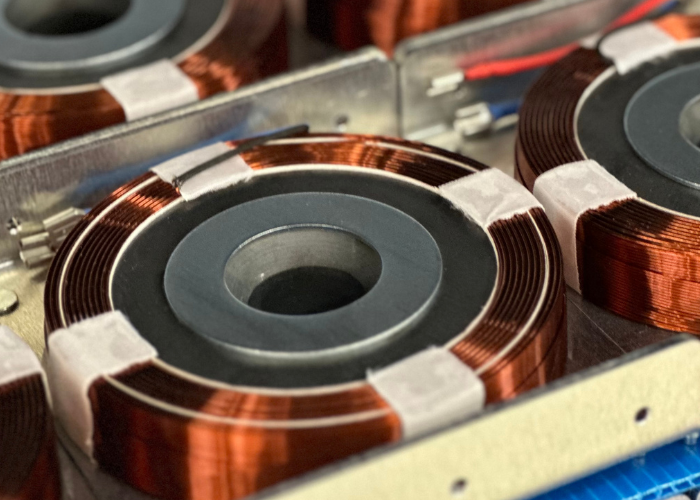

With our state-of-the-art 250,000 sq. ft. manufacturing facility in LaFox, IL (just 50 miles outside Chicago), we help you avoid costly tariffs and supply chain risks while delivering unmatched quality and speed to market. Our advanced capabilities—including precision machining, assembly, and supply chain support—enable global partners to bring high-quality products to market faster.

LaFox, Illinois